MatAIM –

Accelerating Material & Process Innovation

MatAIM –

Accelerating Material & Process Innovation

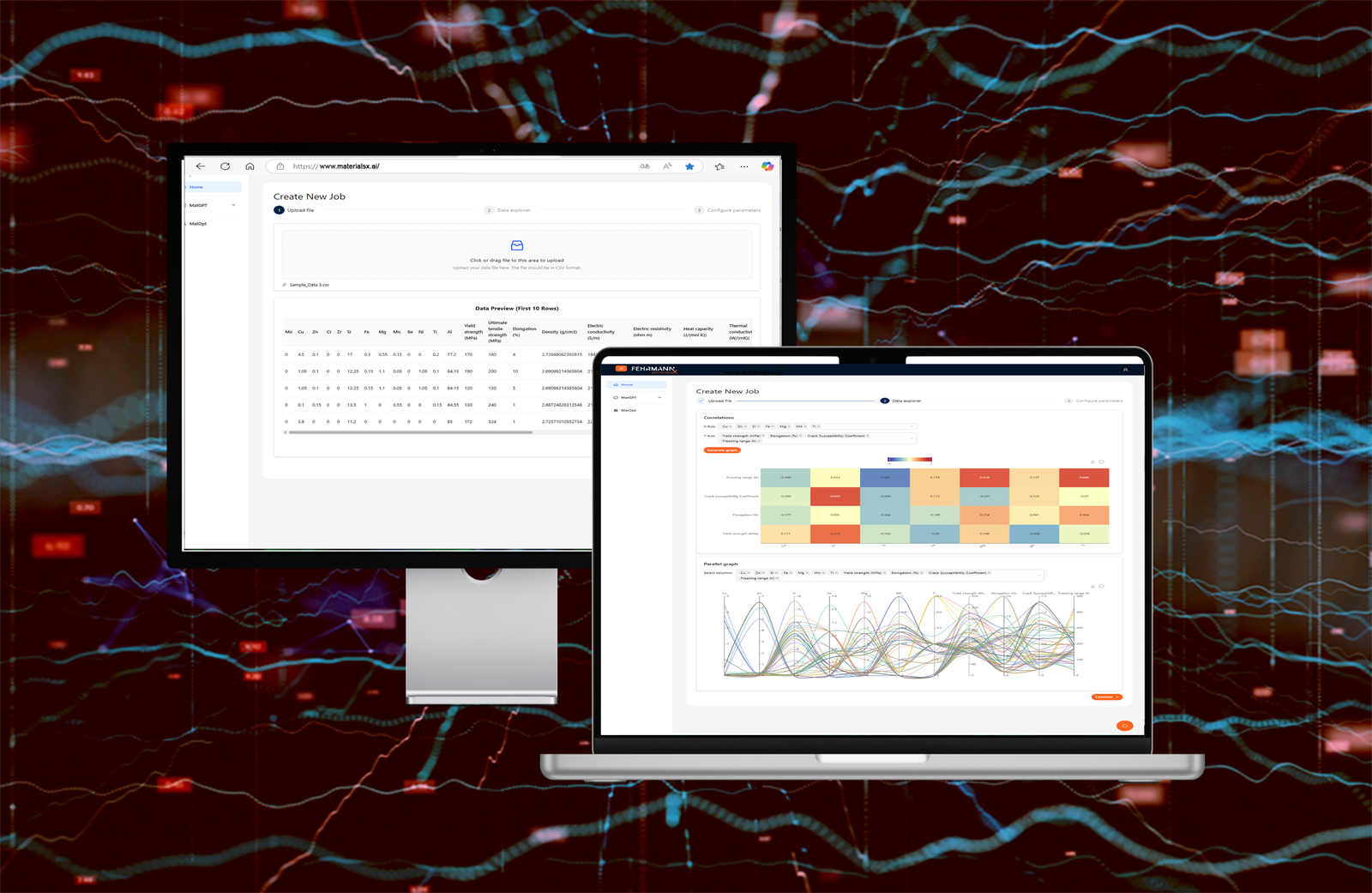

With MatAIM, industrial enterprises identify new materials and process improvements within minutes – enabling more efficient production, optimized materials, and faster product development.

Our AI-powered simulation software analyzes over 1,000 material combinations and delivers multi-scale material and process insights – fast, secure, and fully compliant with EU GDPR and the EU AI Act.

Thanks to its flexible MACH architecture, MatAIM integrates seamlessly into existing IT environments.

Why MatAIM?

Why MatAIM?

MatAIM dramatically accelerates time-to-market. Instead of waiting weeks for test results, MatAIM provides precise predictions of chemical, physical, and mechanical properties – including microstructures – within minutes.

Developing new materials has traditionally been costly, complex, and risky. As a result, ongoing production processes were rarely optimized due to uncertainty and high experimental effort.

MatAIM changes this fundamentally!

AI-driven simulations identify optimal material compositions and process parameters in minutes – highlighting opportunities and risks before time and budget are invested in physical experiments.

By integrating MaterialsX tools seamlessly into existing systems, industrial companies can now unlock untapped potential both in series production and in product development.

Key Benefits

MatAIM drastically reduces physical tests and prototypes for aluminum alloys. Development cycles that once took months can now be reduced to just weeks or even days.

Companies gain speed and agility, respond faster to customer and market demands, and bring new aluminum alloys to market with confidence. Fully GDPR- and EU Act-compliant, the platform integrates smoothly into existing processes and scales with business needs.

Capabilities

From concept to serial production, MatAIM supports every stage of the value chain for aluminum alloys. Automated validation speeds up approvals, data-driven predictions secure decision-making, and overall efficiency increases across departments.

This ensures that new aluminum alloys move into industrial use faster, more reliably, and at lower cost.

Boost Your Productivity

Boost Your Productivity

With MatAIM, aluminum alloy R&D becomes a true growth driver. Development time, testing effort, and costs drop significantly, while precision and reliability increase. Companies benefit from validated innovations, shorter approval cycles, and data-driven decision-making – securing a competitive edge in the global market.

Industries

Industries

MatAIM empowers industries worldwide to develop, simulate, and validate advanced aluminum alloys and processes – faster, safer, and more efficiently.

FAQs

Questions?

Questions?

As generative AI evolves rapidly, many questions arise. Every question is valuable – just ask!

Within weeks, thanks to modular architecture and cloud integration.

Scalability, data security, and flexible usage at any time.

Yes – from startups to enterprises, thanks to flexible modules.

MatGPT complies with the highest security standards, including ISO certifications.